The Classic Aero is equipped with carbon fiber/fiberglass outriggers. As with the Winged Aero and Maas 24 you will need to lay a small bead of silicone around each bolt hole on the deck and position the rigger over the holes (a second person is useful here).

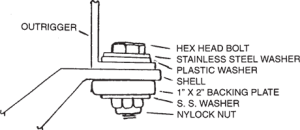

On the Aero riggers, the two bolts forward screw into stainless steel threaded inserts; the two aft bolts pass through backup washers and are secured with nylon lock nuts. You will have to remove the inspection port and storage bag behind it to install these. If you put a bead of silicone on the fender washer it will help to hold the washer in place as well as provide additional waterproofing. Start with the forward bolts and tighten until both are barely snug, then slide the two aft bolts into position. Now go back and tighten down the forward bolts, then finish with the aft bolts. The forward bolts can be tightened with the screw- driver alone. You will need to use the wrench to hold the nuts in place aft while you tighten these bolts. Replace the bag and inspection port, wipe off any excess silicone; the silicone will be fully cured in a day.

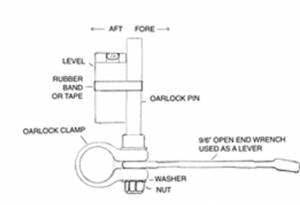

The pins and oarlocks are installed with two crescent wrenches or a 9/ 16 and a 5/8 inch open end or box wrench. We suggest that you place the pins as close as possible to the outside end of the slot in the rigger, and equidistant from the centerline of the boat. To accomplish this it is easiest to measure from the outside edge of the far seat track to the inside edge of the pin. When adjusted, tighten firmly. A tip is to leave the flat face of the shoulder of the pin parallel to the side of the shell. That way, a quick glance at the pin will tell you if the pin has loosened and requires tightening. Reminder: you should check the tightness of those bolts every few months, especially if you use the shell frequently.